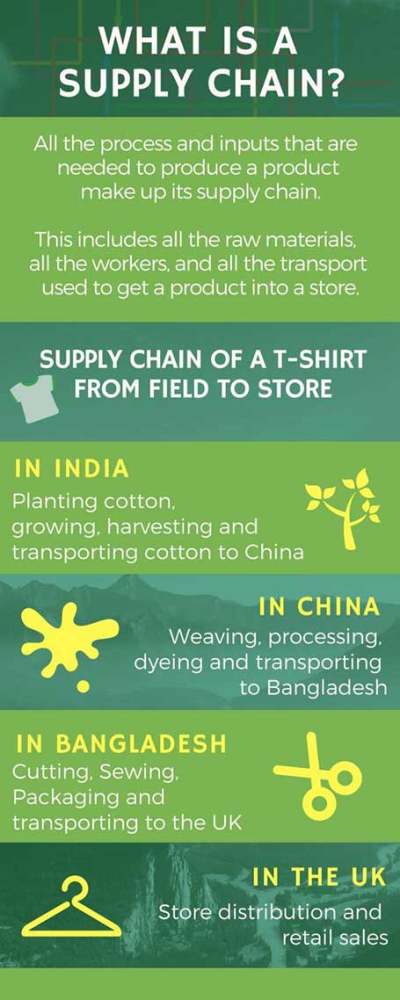

Universally worn and a wardrobe essential for many people, t-shirts are perhaps the cheapest and easiest type of clothing to design, manufacture and sell. The basic t-shirt has therefore become a cornerstone of the fast fashion industry: made quickly and cheaply, worn for a season, and then discarded.

Fashion t-shirts can be cheap to produce but they can be sold for hundreds or even thousands of pounds. And they contribute to the huge carbon cost of the clothing industry.

This guide will help you answer the questions around who made your clothes, under what conditions, and at what impact on the environment.

This guide includes some of the companies seeking to address issues in the clothing industry, by telling you more about where your garments are made and ensuring better practices.

They're doing something different to many of the brands featured in our high street clothes guide, which are likely to be linked to sweatshop conditions, forced labour and environmental pollution, particularly fast fashion brands like BooHoo and Pretty Little Thing.